Real-time quality data automatic collection and analysis

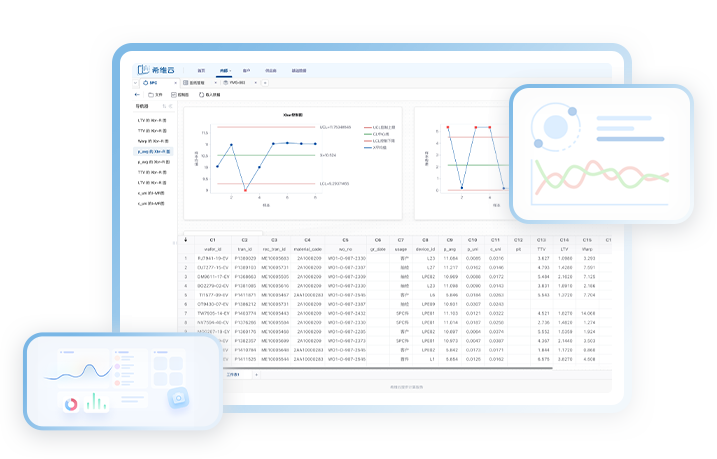

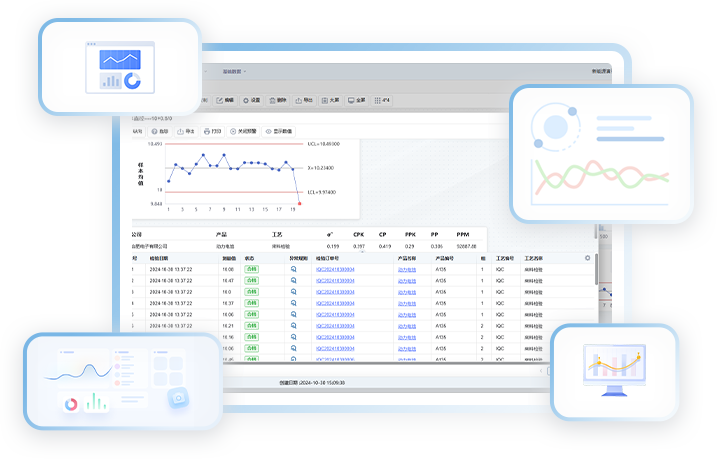

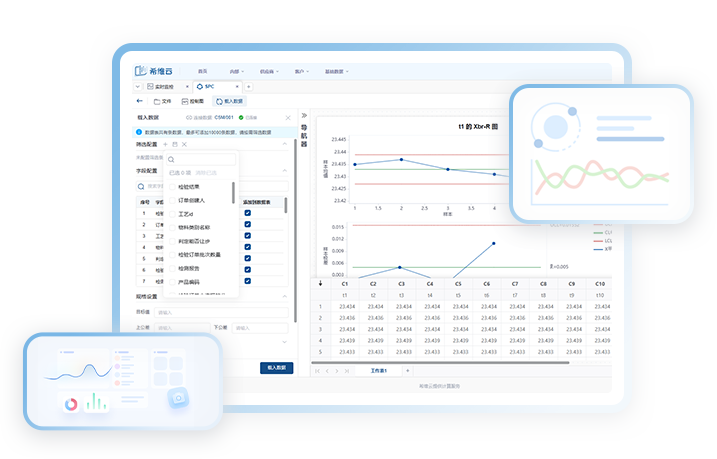

A process monitoring and quality management tool designed specifically for advanced manufacturing enterprises. The system is directly connected to industrial equipment, automatically collects production line data, and generates control charts (such as X-Bar R chart, P-NP chart, C chart, U chart) in real time, replacing traditional manual recording and offline analysis modes, greatly improving efficiency. When key parameters deviate from the preset range, the system will automatically trigger a graded alarm mechanism to help quickly locate abnormal links, shorten problem response time, and reduce the risk of defective products. Meanwhile, it supports multi-dimensional analysis and displays core indicators in real-time.

Real-Time Monitoring

Abnormal warning

Multi-dimension analysis

Visual Dashboard

Flexible Adaptation

Directly connect MES/MOM, SCADA, PLC, IOT, sensors, and even any database equipment to automatically collect data and generate control charts, eliminating manual recording and reducing manual intervention.

Real-Time Monitoring

Based on preset rules, automatically trigger alarms to help on-site personnel respond quickly and reduce the production of defective products.

Abnormal warning

Support multi-dimensional analysis by device, process, batch, etc., to quickly locate the root cause of problems.

Multi-dimension analysis

Real time display of key indicators such as CMK, CPK, PPK, defect rate LAR、FDPPM), Assist management in making efficient decisions.

Visual Dashboard

Support multiple protocols and scenarios to match complex industrial environments.

Flexible Adaptation

Accurate positioning problem

By monitoring and analyzing key indicators of the production process in real-time, quality issues can be quickly identified and addressed, significantly improving product consistency and stability.

Lean Manufacturing

Through preventive quality control, significantly reduce the production of substandard products, lower scrap rates and rework rates. Directly reduce waste of raw materials, labor costs, and equipment depreciation losses.

Optimize Production Processes

By analyzing production data, enterprises can identify bottlenecks and inefficient links in the production process, and make corresponding optimization and improvement to enhance overall production efficiency.

Enhance Decision-Making Capabilities

Based on a large amount of data collected and analyzed in real time, management can more accurately grasp production quality conditions and formulate more scientific and reasonable production and management strategies.

Consulting Prices

Recommend the best solution for you

Reservation

One click appointment, expert demonstration

Contact Number

400-105-9339

Reservation

Consult

Schedule A Demo

*Your name

*Phone Number

*Position Affiliation

*Corporate Name

*Products Of Interest

*Requirement Description

Consulting Prices

*Your name

*Phone Number

*Position Affiliation

*Corporate Name

*Products Of Interest

*Requirement Description