End to end full industry chain, modular quality management

To address the common problems of quality data scattered in various systems, unpredictable quality risks, untraceable quality issues, uncontrolled supply chain quality, high quality losses, low product added value, and inability to utilize quality data in manufacturing enterprises, we provide a standardized one-stop enterprise supply chain quality collaborative management platform for industry customers

Realize quality closed-loop and collaborative management throughout the entire product lifecycle and industry chain, change the current situation of "firefighting" quality management in the industry, and achieve quality management at the forefront. Let data play its due value, truly sustainably improve quality, transform quality from a cost center to a profit center, and continuously enhance the core competitiveness of the enterprise.

End-To-End

Quality Management

Full Process

Quality Traceability

Supply Chain Quality Collaboration

High Scalability And Ease Of Use

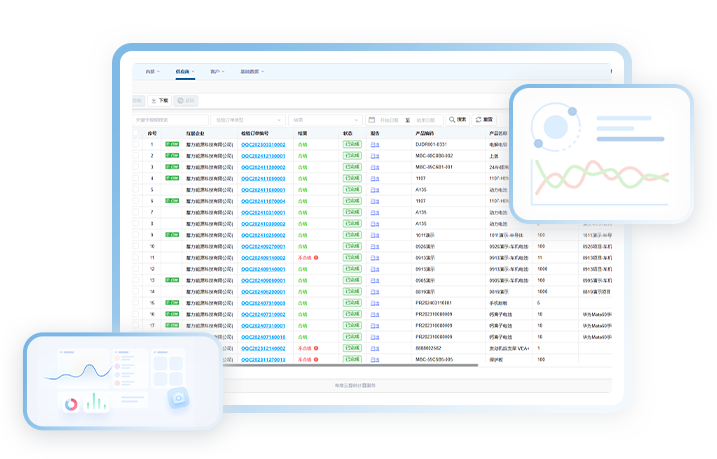

Covering the entire quality management scenario from R&D to manufacturing, after-sales, and supply chain, eliminating information silos of quality data, putting quality management at the forefront and achieving efficient collaboration between departments, automatic synchronization of the three core files, avoiding quality problems caused by excessive reliance on traditional human collaboration models, and ensuring quality consistency.

Through end-to-end deep collaboration and quality data coverage across the entire chain of research, production, supply, sales, and service, we fundamentally avoid quality data silos, achieve one click traceability of quality issues, and truly sustainably improve quality.

End-To-End<br>Quality Management

Quality management process covering the entire product lifecycle, quality related business processes, and synchronized management of business data.

The platform has excellent openness and can achieve efficient integration with other systems through standard APIs, avoiding quality data silos. With just one click, you can trace the entire quality lifecycle and supply chain, supporting traceability to different particle levels such as individual pieces.

Full Process<br>Quality Traceability

Through deep collaboration in quality, we can avoid situations where the authenticity of supplier quality data cannot be guaranteed, and where supplier quality capabilities cannot be scientifically evaluated based on data.

Make supplier quality visible, controllable, and preventable, avoid chain owners paying for supplier quality, and achieve a win-win situation for both chain owners and supply chains.

Supply Chain Quality Collaboration

A modular quality management system that supports building from a single module and gradually establishing the full lifecycle quality management of the COP main value chain and PDCAS processes to empower continuous quality appreciation.

Supporting the expansion from individual factories to conglomerates, local factories to globalization, avoids the problem of traditional systems taking one step at a time and even redundant construction due to the inability to sustain expansion.

Mobile and PC can synchronize with one click, and users who know how to use WeChat will use the Xiwei Cloud Quality Management Platform, ensuring that frontline users can quickly get started and avoiding the problem of traditional systems being rejected by users due to high complexity.

High Scalability And Ease Of Use

Data-Driven

By implementing data-driven management, intelligent analysis, and standardized collaboration throughout the entire process, we aim to build a quality moat that covers the entire lifecycle from raw materials to end products. This will help companies explore quality data assets and maximize the value of their data.

Customer Trust

Implementing one click quick traceability not only efficiently traces back to the internal source of quality issues such as research and development, but also to suppliers, maximizing customer satisfaction and trust.

Win Orders, Earn Profits

Win high-quality orders with quality and make profits through quality. Winning orders with excellent quality capabilities, transforming the cost center into a profit center, reducing quality costs, improving product qualification rates, and achieving maximum profit.

Real-Time Analysis

Change the current situation of lagging and formalized analysis in traditional quality management methods, conduct real-time and efficient data statistical analysis, accurately locate the root cause of quality problems and provide early warning and prediction, promote continuous improvement of quality, and further strengthen the moat of core competitiveness of enterprises.

Industry chain level management

Implement data-driven management of suppliers to achieve deep and efficient collaborative operations, while also collaborating agilely with customers to increase the reliability, agility, and other core competitiveness of the enterprise and supply chain.

Globalization helps

A product architecture that meets the needs of groupization and globalization, supports the global business layout of enterprises, and meets the needs of sustainable development and future growth.

Consulting Prices

Recommend the best solution for you

Reservation

One click appointment, expert demonstration

Contact Number

400-105-9339

Reservation

Consult

Schedule A Demo

*Your name

*Phone Number

*Position Affiliation

*Corporate Name

*Products Of Interest

*Requirement Description

Consulting Prices

*Your name

*Phone Number

*Position Affiliation

*Corporate Name

*Products Of Interest

*Requirement Description