FMEA analysis standardization and process standardization.

Assist enterprises in early identification and prevention of faults, promote continuous improvement through data analysis and optimization suggestions. On the one hand, by collecting relevant data about products, services, or processes, establishing a database for analysis to identify potential failure modes and effects. On the other hand, assess the risks of potential failure modes and rank them based on their severity and frequency. Assist enterprises in developing improvement plans to reduce the occurrence and impact of potential failures.

Centralized Management

Rpn Screening And Early Warning

Closed-Loop Management

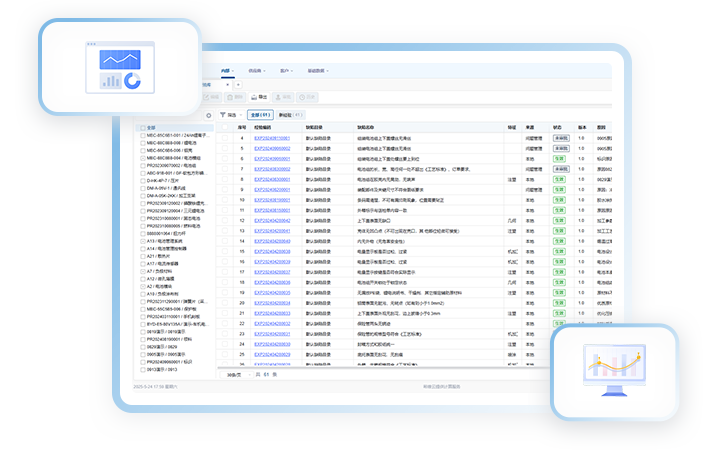

Three Major Documents Synchronized

Centralize the management of all information such as failure phenomena, failure impacts, potential causes, etc., maximizing the savings of personnel and team time costs, and easily applying it to all projects, flexible and fast.

Centralized Management

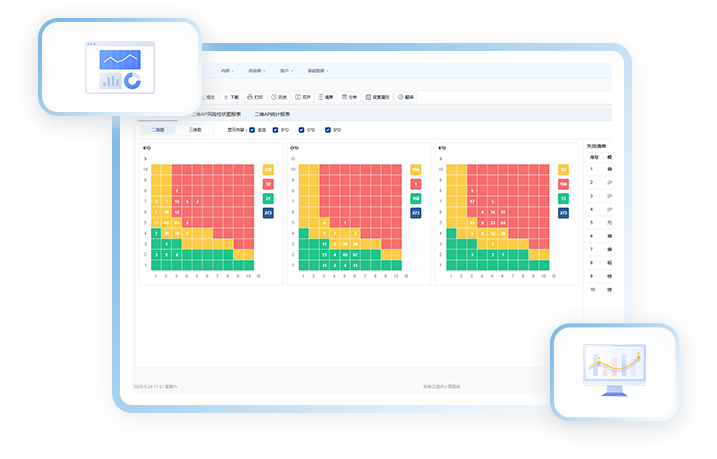

Setting the threshold of RPN, quickly querying high-risk projects and implementing measures, can detect the RPN changes of already critical high-risk RPN values after upgrading in the S/O/D dimension, without changing the actual RPN, and quickly identify potential high-risk.

Rpn Screening And Early Warning

Realize the rapid collection and summary of quality information during product production and delivery, manage customer complaints, track and monitor the handling process of problems, ensure correction and prevention, synchronously trigger DFMEA updates, implement measures, and improve and accumulate experience in the experience base.

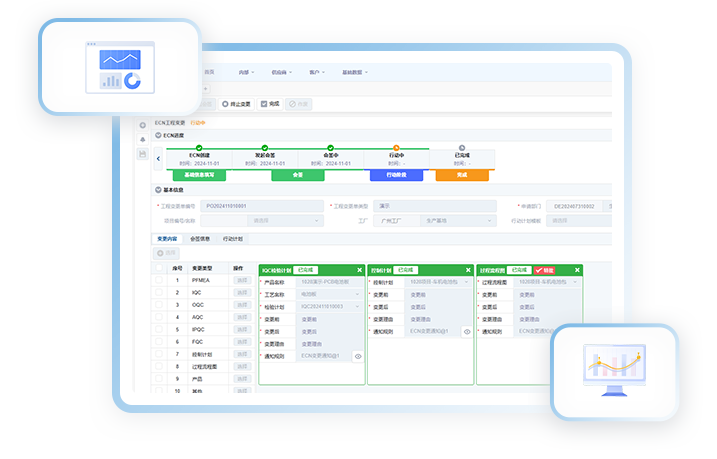

Closed-Loop Management

Structured creation process flowchart FMEA、 The three major document management processes of the control plan only require maintenance of the basic database. When the database content changes, the system automatically changes the associated files and sends the change information to the corresponding personnel. When there is an engineering change, the system automatically adjusts the content of the three major files.

Three Major Documents Synchronized

DFMEA Knowledge Base

Assist clients in establishing an FMEA knowledge base

Establish a hierarchical relationship between the list of historical issues and structured failure data

Help quickly identify supplier product and process failure risks

Establish a database of failure phenomena, effects, and potential causes to maximize the savings of personnel and team time costs

Staff can directly select invalid information from the knowledge base, which can improve work efficiency by more than 50%

Structured process documents

Provide various types of automated management processes for process documents

Provide comprehensive one-stop management of structured PFMEA, CP, inspection plan, characteristic list, drawings and other process documents

Optimize quality system document control management

Implement problem improvement and FMEA closed-loop management

Record the information before and after FMEA and control plan modifications, and automatically generate a data change list after upgrading.

Consulting Prices

Recommend the best solution for you

Reservation

One click appointment, expert demonstration

Contact Number

400-105-9339

Reservation

Consult

Schedule A Demo

*Your name

*Phone Number

*Position Affiliation

*Corporate Name

*Products Of Interest

*Requirement Description

Consulting Prices

*Your name

*Phone Number

*Position Affiliation

*Corporate Name

*Products Of Interest

*Requirement Description